Product features

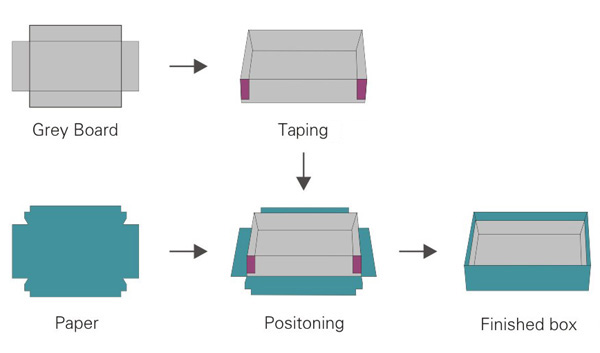

ZS-6418 automatic rigid box making machine adopts internationally accepted high precision feeder gluing machine, suck board type four corner taping machine, fiber-optic sensor positioning system, cam servo forming machine, with stable high-performance,suitable for production of various rigid boxes.

1. High automation, greatly save labor and increase efficiency.

2.PLC and touch screen type man-machine control system, simple operation, easy to learn.

3.High accuracy feeder with paper separating system, ensure paper feeding quick and stable.

4.Automatic lifting plate, easy and fast material loading.

5. Glue tank with automatic stirring,timing heat and constant temperature function.

6.Servo optical fiber positioning system, high positioning accuracy ( ±0.2mm).

7.High accuracy linear guide and screw adjust size, easy and fast die changing.

8.Robotic arm automatic pick up and draw box, avoid scratch.

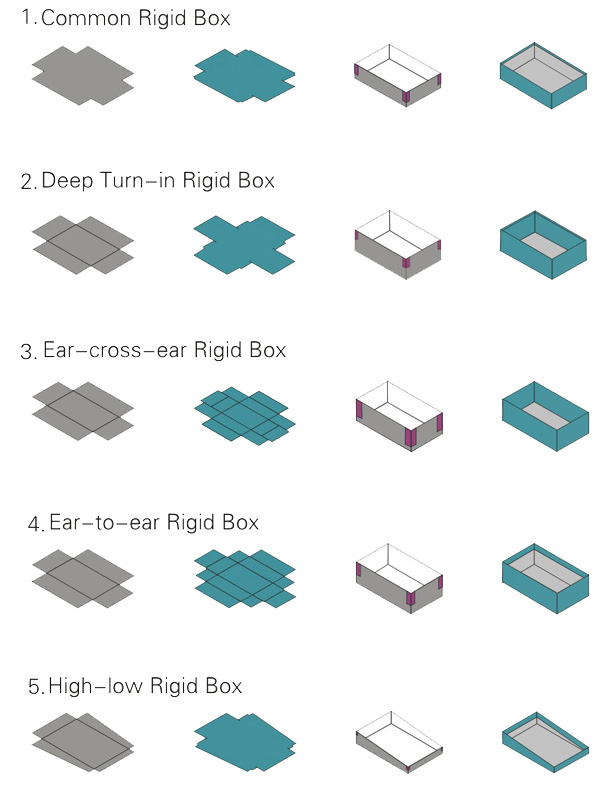

9.Servo control box forming, the four heads can work independently, suitable for various styles of box.

Product application

Widely used in gift box, moon cake box, mobile phone box, shoes box, watch box, jewelry box, cosmetic box, tea box, medicine box, etc.

Gift box

Gift box

Moon cake box

Moon cake box

Tea box

Tea box

Cosmetic box

Cosmetic box

Mobile box

Mobile box

Product parameters

| Model | ZS-6418 | |

Paper size | A min | 95mm |

| A max | 610mm | |

| B min | 180mm | |

| B max | 920mm | |

| T1 | 80-300g/m2 | |

Cardboard size | C max | 580mm |

| D max | 920mm | |

| T2 | 1-4mm | |

Finished box size(W*L*H) | L min | 100mm |

| L max | 600mm | |

| W min | 60mm | |

| W max | 400mm | |

| H min | 12mm | |

| H max | 120mm | |

Turn-in paper size | R min | 15mm |

| R max | 90mm | |

Ear cross ear folding size | L max | 120mm |

Positioning accuracy | ± 0.2mm | |

Production speed | 1 time forming | 25-30pcs/min |

2 times forming | 20-25pcs/min | |

3 times forming | 18-23pcs/min | |

4 times forming | 15-20pcs/min | |

Air pressure | 0.6-0.8Mpa | |

Power supply | 380V/50Hz 3phases | |

Total power | 15kw | |

Machine weight | 5800kg | |

Machine dimension | L6600×W4500×H3200mm | |